Fábrica de moldes de injeção de plástico de alta qualidade e preço barato

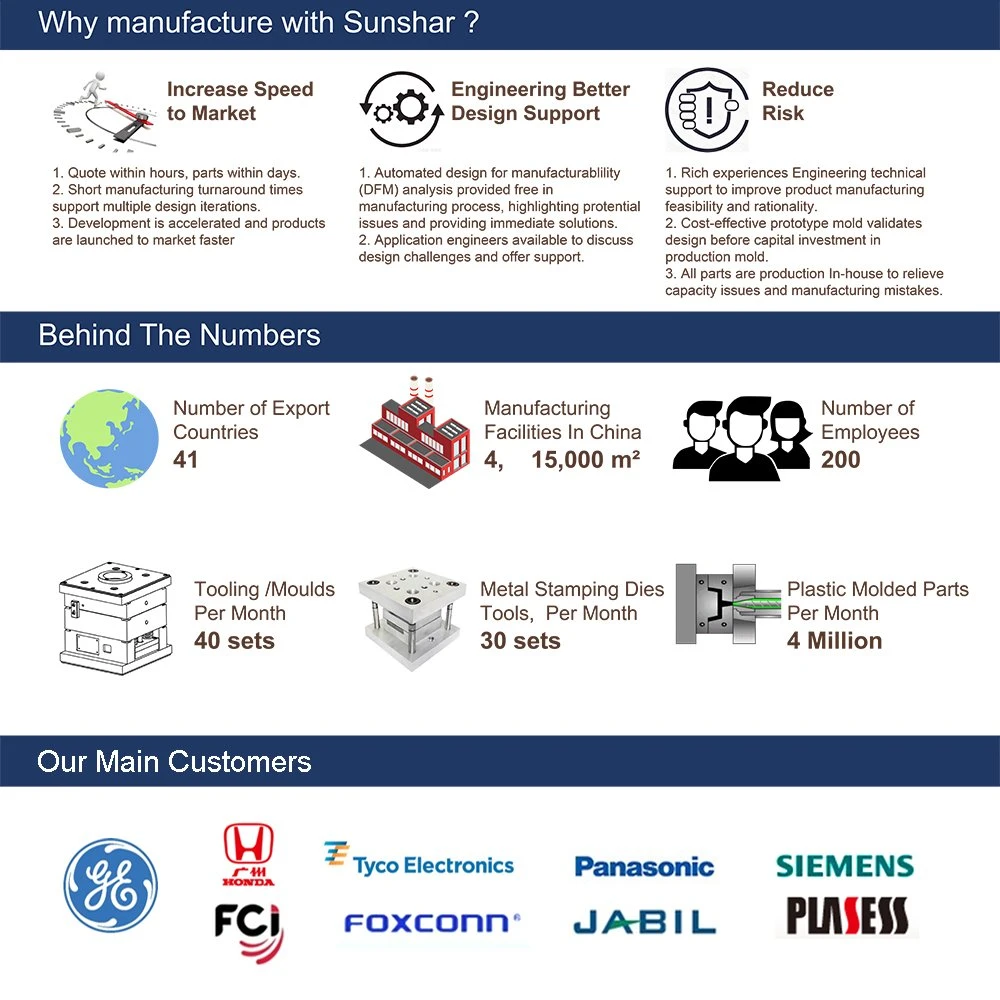

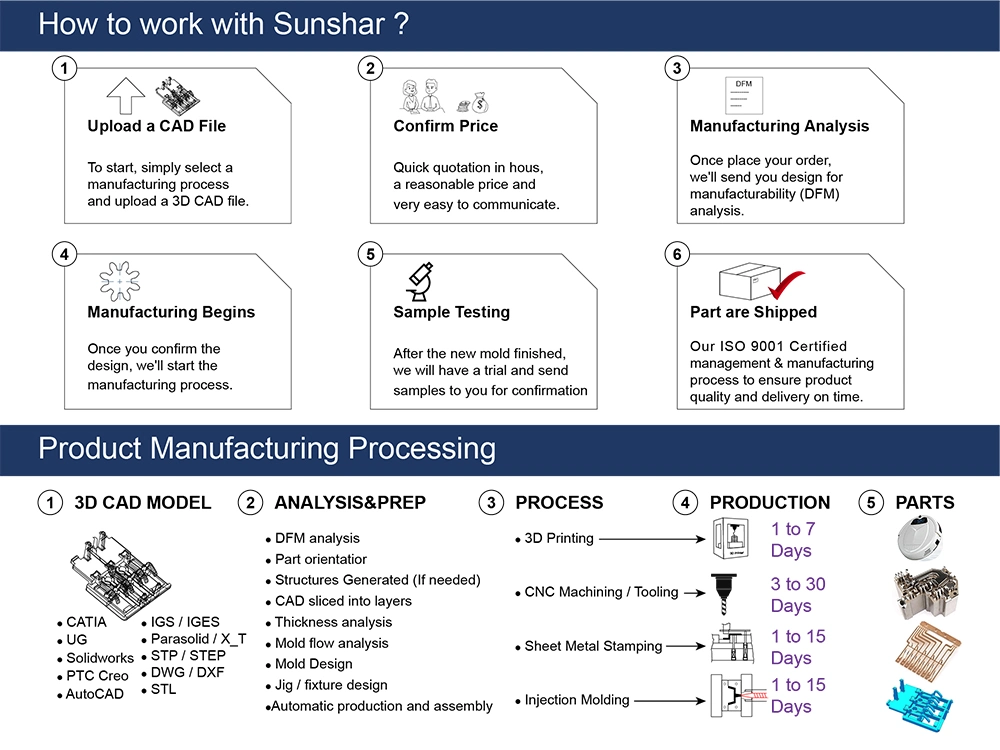

Por que escolher a Sunshar? A Sunshar fornece serviço completo para moldagem por injeção de plástico de alto volume e té

Informação básica

| Modelo Nº. | moldagem de plástico |

| Corredor | Corredor quente |

| software de design | e |

| Instalação | Fixo |

| Certificação | TS16949,ISO |

| Padrão | HASCO |

| Personalizado | Personalizado |

| Tratamento | HRC48-52 |

| Aço | 1.2344 |

| Sistema de câmara quente | Yudo, Mold Masters, Synventive, Husky |

| Prazo de entrega | 15-30 dias |

| Mercado de exportação | Euro, EUA, América do Norte/Sul, Ásia |

| Pacote de transporte | Embalagem de madeira |

| Especificação | 400*600*421 |

| Marca comercial | Sunshar |

| Origem | China |

| Código SH | 8480719090 |

| Capacidade de produção | 100 |

Descrição do produto

| SUNSHAR PRECISION TECHNOLOGY CO., LTD | |

Envie para nós